TOKYO, JAPAN, December 08, 2022

- New circular LEXAN™ polycarbonate (PC) film offerings using post-consumer recycle (PCR) feedstock developed to transform global recycling challenges into business opportunities

- Significant value chain benefits vs. virgin PC film products across consumer goods, electronics, automotive, construction and more

- Sustainable flame retardant (FR) and non-FR high-functionality film solutions on display at FilmTech 2022 in Tokyo

SABIC, a global leader in the chemical industry, is taking another big step towards circularity with new LEXAN™ film solutions based on PCR resins that may offer equivalent performance to virgin PC film products while potentially offering significant sustainability benefits. As part of SABIC’s TRUCIRCLE™ portfolio and services, the new PCR based film grades include several flame retardant and non-FR high-functionality additions to the company’s wide range of graphic, display, electrical, security and ID card films and will be showcased during FilmTech from December 07 to 09 at Makuhari Messe Tokyo in Hall 6, Booth #28-52.

“We are firmly committed to a future where plastics will never end up in our environments, landfills or oceans,” states George Kipouras, Business Development Manager for SABIC’s Functional Forms business. “Our innovative PCR film products have been developed to make this vision come true without compromising the familiar high mechanical properties and surface appeal of polycarbonate film.”

“The extended LEXAN™ PCR films portfolio can be a real game changer, potentially helping all players along the value chain reduce their environmental footprint and transform global recycling challenges into business opportunities,” adds Thomas Hsieh, Product Manager for SABIC Functional Forms. “The high PCR content in these products may enable electronics companies to achieve higher EPEAT ecolabel recognition and generate more incentive for Environmentally Preferred Purchasing (EPP).”

PCR-Based LEXAN EFR Film Solutions

SABIC’s LEXAN EFR polycarbonate films offering has been updated with two new PCR products combining high flame retardancy (UL 94 V0 at 0.38 mm and VTM0 at 0.178 mm) with excellent mechanical and electrical properties, high chemical, hydrolytic and puncture resistance, optimal dimensional stability at high temperatures and the characteristic aesthetics of polycarbonate film. Featuring full non-chlorine and non-bromine compliance and a PCR content of 30 and 60 percent, respectively, LEXAN EFR535 and EFR 565 films may provide superior eco solutions for global electrical and electronics manufacturers who seek to advance beyond current regulations by eliminating halogen flame-retardants and supporting a circular plastics economy.

The new PCR EFR film grades are fine matt on one side and velvet on the other. Potential applications include battery packs and adaptors for computers, laptops, and smartphones, heat/dielectric shielding and insulation barriers, die-cut insulators and spacers, labels and overlays, e.g. in-home appliances.

Non-FR PCR-Based LEXAN Film Solutions

SABIC’s non-FR PCR LEXAN films have seen a major sustainability upgrade from first-generation products with 30 percent PCR content to our second-generation LEXAN 5B85 film with 80 percent PCR content, which may deliver carbon footprint reductions of up to 50 percent vs. comparable virgin polycarbonate films. With scratch and wear resistance on textured sides, they offer high impact and temperature resistance, significant dimensional stability and excellent processability from thermoforming, hydroforming and bending to embossing and die cutting. Third-generation technology is also expected to include PMMA/PC coextrusions.

Ideal for multi-layer printing, LEXAN non-FR PCR films can be screen-printed without pre-treatment using traditional solvent-based or water-based, UV or infrared drying inks. Potential applications include multi-layer printed overlays, high-performance labeling for home appliances, LED/LCD displays for audio and video equipment, and automotive dashboards.

High-Functionality LEXAN film series

The comprehensive portfolio of SABIC’s uncoated graphic, coated, display, electrical, security and ID card films is complemented by a range of LEXAN™ DP film grades that are specifically designed to increase the adhesion of UV inks to digitally printed adhesive labels and decals. These film products may show exceptional ink registration and resolution as well as superior heat resistance and enhanced dimensional stability across a wide range of materials, thicknesses, UV digital printers and ink types. LEXAN DP films are available with velvet, primed (coated) and/or high-gloss finished surfaces, depending on the grade. One of the latest developments is a digital print film with a hard coat on the first surface and a primed second surface for UV digital ink print and adhesive applications.

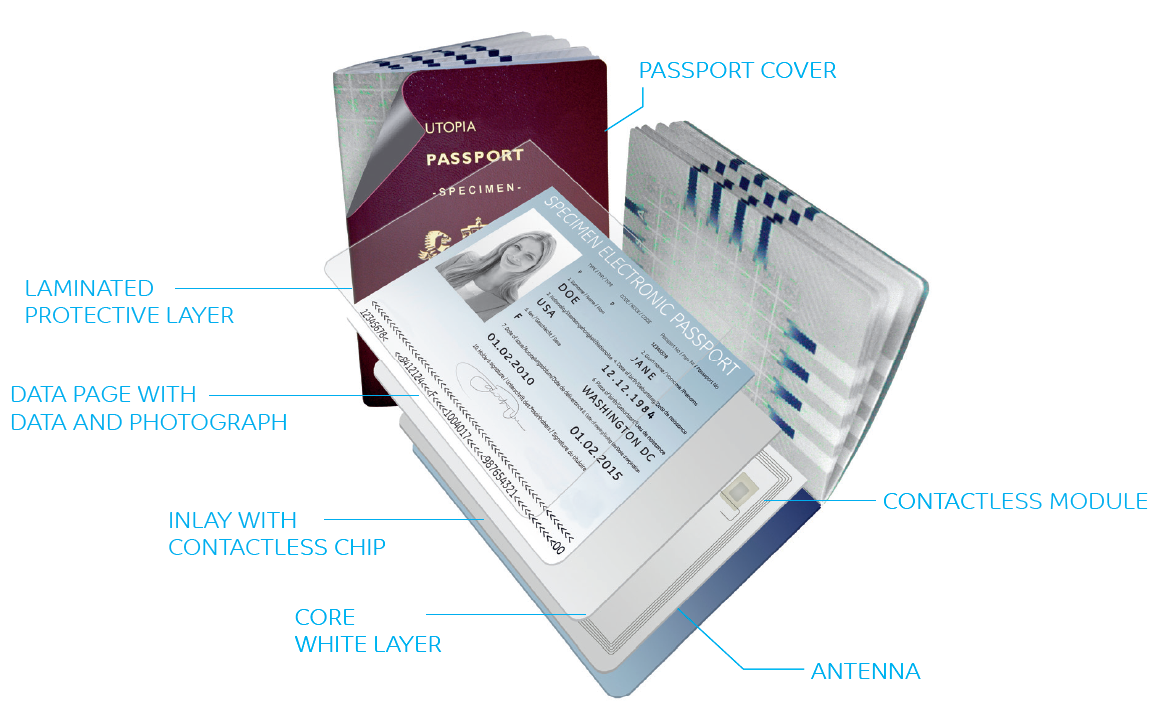

In addition, SABIC has introduced LEXAN SDCX film technology for ID cards, which combines a white-opaque or transparent core layer with a clear, laser-engravable top layer to avoid the challenges of handling separate thin film layers. The company’s new, highly transparent SD overlay film will be available in gauges of 50 and 100 microns and can be laminated in standard ID card production processes, facilitating the integration of personal identification and security features.

“SABIC's scientists are continually striving to exceed the expectations of customers with advanced material solutions designed to combine sustainable innovation,” says Lori Louthan, Global Segment Leader for SABIC Functional Forms. “While LEXAN film products are inherently recyclable thanks to their thermoplastic resin matrix, our growing PCR-based and renewable offering represents a major step forward towards true circularity and reducing our environmental impact.”

END

For more information visit our website or connect with us on LinkedIn or Facebook.

PHOTOS AND CAPTIONS

SABIC has introduced new LEXAN™ EFR grades based on post-consumer recycled (PCR) feedstock, combining halogen-free flame retardancy with excellent mechanical and electrical properties, high chemical, hydrolytic and puncture resistance, optimal dimensional stability at high temperatures and the characteristic aesthetics of polycarbonate film.

SABIC’s new non-FR PCR LEXAN™ films with up to 80 percent PCR content can deliver carbon footprint reductions of up to 50 percent vs. comparable virgin polycarbonate films, while offering high scratch, wear, impact and heat resistance together with excellent dimensional stability, flexible processing and ease of printing.

LEXAN™ DP single-sided primed polycarbonate film grades are specifically designed to increase the adhesion of UV inks to digitally printed adhesive labels and decals, showing exceptional ink registration and resolution as well as superior heat resistance and enhanced dimensional stability across a wide range of materials, thicknesses, UV digital printers and ink types.

SABIC’s highly transparent new SD overlay film will be available in gauges of 50 and 100 microns and can be laminated in standard ID card production processes, facilitating the integration of personal identification and security features.

---------------------------------

NOTES TO EDITORS

- SABIC and brands marked with ® and ™ are trademarks of SABIC or its subsidiaries or affiliates.

ABOUT SABIC

SABIC is a global diversified chemicals company, headquartered in Riyadh, Saudi Arabia. It manufactures on a global scale in the Americas, Europe, Middle East and Asia Pacific, making distinctly different kinds of products: chemicals, commodity and high-performance plastics, agri-nutrients and metals.

SABIC supports its customers by identifying and developing opportunities in key end-use applications such as construction, medical devices, packaging, agri-nutrients, electrical and electronics, transportation and clean energy.

SABIC recorded a net profit of SR 23 billion (US$ 6.15 billion) in 2021. Sales revenues for 2021 totaled SR 174 billion (US$ 46.6 billion). Total assets stood at SR 318 billion (US$ 84.9 billion) at the end of 2021. Production in 2021 stood at 58 million metric tons.

The company has more than 31,000 employees worldwide and operates in around 50 countries. Fostering innovation and a spirit of ingenuity, SABIC has 10,090 patents and pending applications, and has significant research resources with innovation hubs in five key geographies – USA, Europe, Middle East, South Asia and North Asia.

SABIC Media Contact

- Nicole Teljeur

- E: Nicole.teljeur@sabic.com

- T: +31 164 291 616

Marketing Solutions

- Stephanie Wakkee

- E: swakkee@marketing-solutions.com

- T: +32 3 31 30 311

This press release and relevant photography can be downloaded from Pressreleasefinder.com. Alternatively, for very high-resolution pictures please contact:

Stephanie Wakkee ( swakkee@marketing-solutions.com , +32 3 31 30 311)

Deutsch

Deutsch

English

English

Española

Española

Français

Français

italiano

italiano

Portugues BR

Portugues BR

日本語 (Japanese)

日本語 (Japanese)

中文 (Chinese - Mandarin)

中文 (Chinese - Mandarin)

한국어 (Korean)

한국어 (Korean)